Follow us on:

CONTACT US | Download the 2021/2022 issue | ©Atlas Copco AB

result

Search

A MAGAZINE FROM ATLAS COPCO GROUP

Sustainable technologies

Markets

Smart manufacturing

Our culture

Service and Consulting

Energy efficiency

SMARTER

manufacturing

Imagine a factory where smart machines operate autonomously and transfer data without any delay. With 5G mobile networks, this will soon be a reality.

With ultra-high speed and reliability, fifth generation (5G) mobile networks will revolutionize industrial manufacturing. The dramatic increase in capacity is a prerequisite for data-consuming technologies like the Internet of Things, intelligent automation, real-time monitoring and machine learning. The network technology is there. The challenge is to optimize it for industrial settings.

Since 2019, the Atlas Copco Airpower factory in Belgium is testing a private 5G network with indoor antennas connecting the shop floor. The goal is to investigate how to best implement 5G and create intelligent manufacturing flows where production data is transferred without delay.

“We are testing how to best connect machines wirelessly and monitor quality and energy consumption in real time, and how to use Automated Guided Vehicles (AGVs) on the shop floor for increased precision and safety,” says Wouter Ceulemans, President of Atlas Copco’s Airtec division that designs and manufactures advanced compressor parts.

“The really exciting learnings will come from the ultra-low latency. 4G is not fast enough to make real-time control possible. With 5G, the delay drops to a minimum, making truly smart manufacturing a reality,” Wouter explains.

“The insights we gain from this test network will naturally benefit our own production flows worldwide, but also help us support our customers. When they get ready to make this big technology leap they will need a partner who understands their challenges, and designs its products accordingly,” says Wouter.

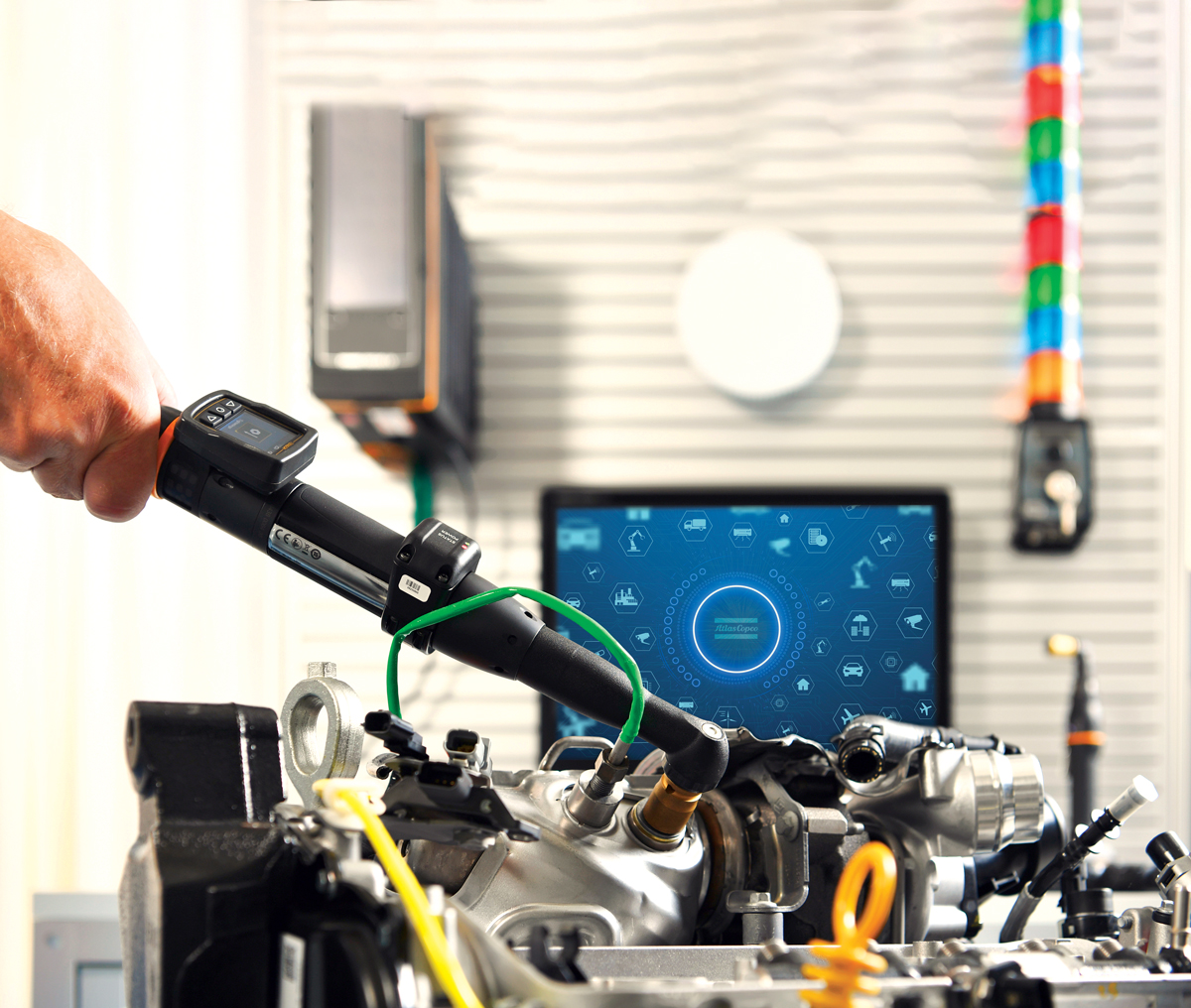

Meanwhile, Atlas Copco Industrial Technique has also installed a private 5G network in its integration lab in Stockholm, Sweden. The network is used to develop 5G ready industrial tool solutions for customers worldwide. This is one of the first 5G implementations for industrial purposes in the world and helps put this kind of network solution to the test.

”Today more than 90% of our industrial tools are connected to our customers’ systems, most of them through fixed couplings. We also provide many wireless systems based on Bluetooth or Wi-Fi. By installing this 5G network we can design, develop and test new products equipped with integrated 5G modules, and thereby support our customers on their journey toward fully connected manufacturing processes,” says Lars Eklöf, President of the Motor Vehicle Industry division.

We are testing how to best connect machines wirelessly and monitor quality and energy consumption in real time, and how to use Automated Guided Vehicles (AGVs) on the shop floor for increased precision and safety”

Wouter Ceulemans

President,

Atlas Copco’s Airtec division